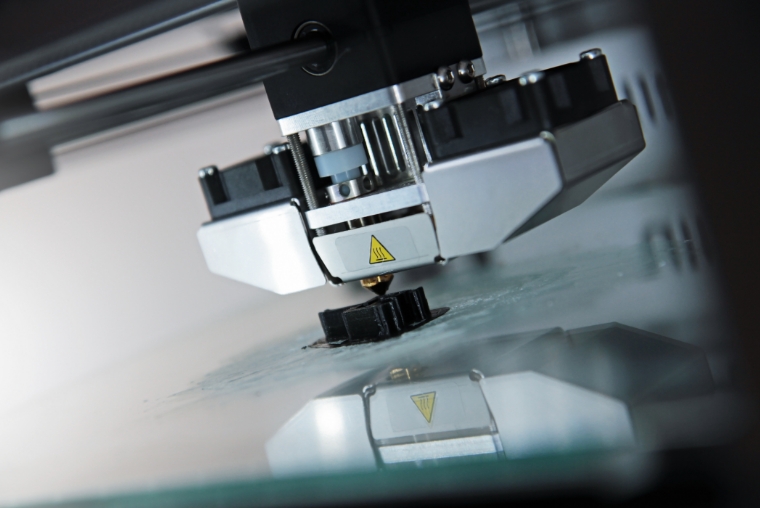

3D printed sockets are conveniently available for small quantities and ambient-only qualification tests.

Advantages of 3D printed sockets over machined sockets are low cost and short lead time. MiS proposes the best customized socket solutions for budgets and applications.

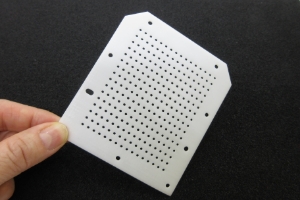

3D printed crystal device tray is available for crystal device visual inspection. Inexpensive solution for quantities from 1 pc.

| Device sizes supported | 7050~2016 |

|---|---|

| Maximum devices on a tray | 256 pcs (16 x 16 array) |

| Tray dimensions | 90×50 mm |

| Operating temperature | Ambient *1 |

| Material | Acrylic |

| Minimum order quantity | 1 pc |

Maximum operating temperature is 260C depending upon the material used and accuracy required.

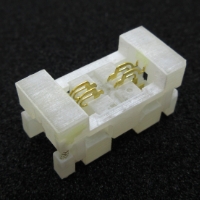

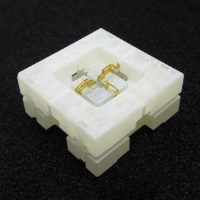

3225 package tray

Zoomed view